The Pressing shop is newly engaged in the construction of prototypes and product development support. We offer product development, modification of existing mouldings, 3D printing, stamping on a prototype of the press (including the production of molds and final surface finishing: grinding, sanding, painting ...).

Product development

- The construction of parts in SolidWorks

- Design optimization of parts according to customer documentation

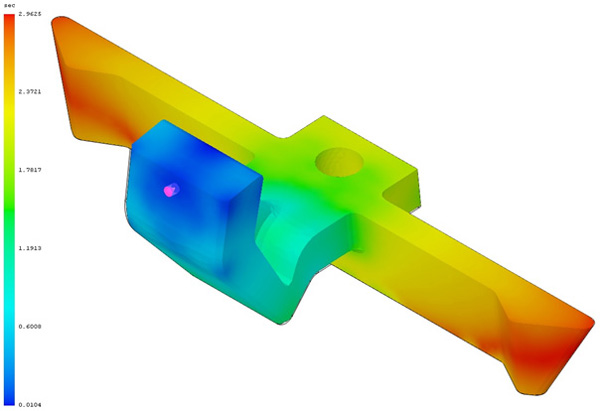

- The basic stress analysis of parts

- The basic plastic flow analysis

- Fotorender of parts and assemblies (for product presentations, catalogs ...)

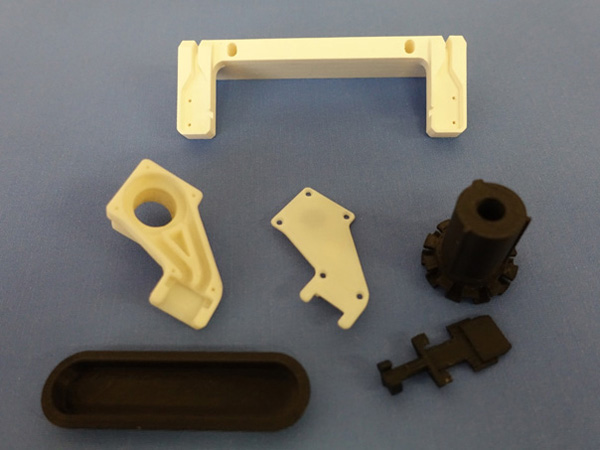

3D Printing

- Professional 3D Printer from Stratasys

- FDM technology with rinse-away support (the possibility of building cavities, complex assemblies ...)

- High precision 0,17 mm

- Material ABS+

- Products can be surface treated (sanding, varnishing…)

- Free calculation (based on 3D model)

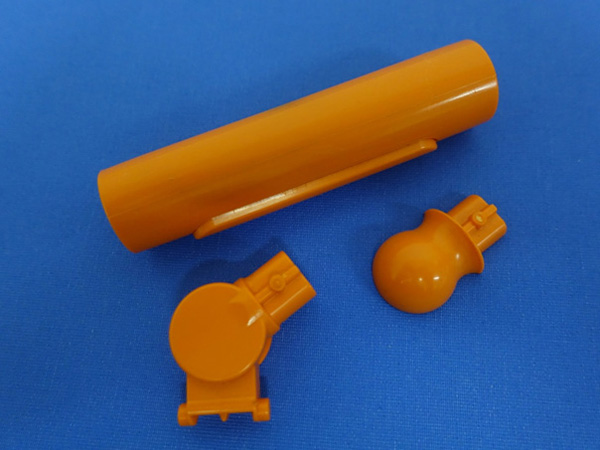

Injection molding prototype

- Use of original granulation from injection molding

- Normally used plastics - ABS, ASA, PA, PS, POM, PP, PE

- Optional color variants and UV stabilizers

- Max. molding mass 6 g

- Max. size forms 84 x 84 x 100 mm

- We take care of design and construction of molds

- Lifetime of the aluminum mold (according to the complexity) ca. 100 ks

- Low cost manufacturing of the mold

- Calculation of production for free